The Complete Guide to Industrial Compressor Repair: Best Practices and Proven Solutions

Industrial compressors are vital components in various manufacturing processes, providing the necessary power to drive pneumatic tools, control systems, and machinery. However, like any mechanical equipment, compressors are subject to wear and tear over time, leading to inefficiencies, breakdowns, and costly downtime. In this comprehensive guide, we will delve into the best practices and proven solutions for industrial compressor repair, equipping you with the knowledge to maintain optimal performance and extend the lifespan of your equipment.

Understanding Industrial Compressors

Industrial compressors play a crucial role in various sectors, from manufacturing and construction to automotive and aerospace industries. Before delving into repair strategies, it’s imperative to grasp the fundamental principles and types of industrial compressors.

- Operating Principles: Industrial compressors work on the principle of reducing the volume of a gas to increase its pressure. This is achieved through mechanical means, where the compressor’s internal components compress the gas, resulting in a higher pressure output. Understanding this principle helps in diagnosing and troubleshooting compressor issues effectively.

- Types of Compressors:

- Rotary Screw Compressors: These compressors use rotating screws to compress the gas. They are known for their high efficiency, continuous operation, and relatively low maintenance requirements. Rotary screw compressors are widely used in industrial applications where a constant supply of compressed air is needed.

- Reciprocating Compressors: Reciprocating compressors employ pistons to compress the gas. They are versatile and suitable for a wide range of pressure and flow rate requirements. However, they may have higher maintenance needs due to the reciprocating motion of the pistons.

- Centrifugal Compressors: Centrifugal compressors utilize rotating impellers to accelerate the gas and convert kinetic energy into pressure. They are preferred for high-volume, low-pressure applications and are known for their compact design and smooth operation.

- Rotary Vane Compressors: These compressors feature vanes that slide in and out of slots to compress the gas. They are often used in smaller industrial applications and are valued for their simplicity, reliability, and quiet operation.

- Applications: Industrial compressors find application in a wide range of industries and processes, including pneumatic tools, air conditioning systems, refrigeration, gas pipelines, and more. Understanding the specific requirements and operating conditions of each application is essential for selecting the appropriate type of compressor.

- Efficiency and Performance: Efficiency is a critical factor in industrial compressor operation, as it directly impacts energy consumption and operational costs. Factors such as compressor design, size, speed, and maintenance practices influence efficiency and performance. Proper selection, installation, and maintenance of compressors are essential for optimizing efficiency and ensuring reliable operation.

- Safety Considerations: Industrial compressors operate at high pressures and temperatures, posing potential safety risks if not handled properly. Understanding safety protocols, including pressure relief valve installation, proper ventilation, and compressor room design, is essential for ensuring a safe working environment and minimizing the risk of accidents or injuries.

Common Compressor Issues

Several factors can contribute to compressor malfunctions, ranging from mechanical failures to operational errors. Some of the most common issues include:

- Air Leaks: Leakage in the compressor system can lead to reduced efficiency and increased energy consumption.

- Overheating: Excessive heat generation can result from inadequate lubrication, improper cooling, or overloading of the compressor.

- Oil Contamination: Contaminants in the compressor oil can cause damage to internal components and compromise performance.

- Worn Components: Wear and tear on components such as valves, seals, and bearings can lead to decreased efficiency and eventual breakdowns.

Best Practices for Industrial Compressor Repair

To address these issues effectively and prevent further damage, follow these best practices for industrial compressor repair:

- Regular Maintenance: Implement a proactive maintenance schedule that includes routine inspections, lubrication, and component replacements as needed.

- Air Quality Management: Invest in quality air filtration systems to remove contaminants and moisture from the compressed air, preventing damage to the compressor and downstream equipment.

- Proper Lubrication: Ensure that the compressor is adequately lubricated according to manufacturer recommendations to reduce friction and wear on moving parts.

- Temperature Control: Monitor and regulate the operating temperature of the compressor to prevent overheating and thermal stress on critical components.

- Training and Education: Provide training for operators and maintenance personnel on proper compressor operation, troubleshooting, and repair techniques to minimize errors and maximize efficiency.

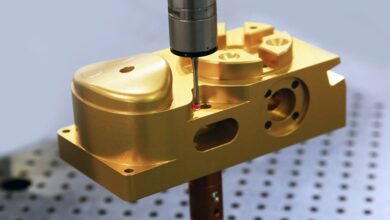

Proven Solutions for Compressor Repair

When faced with compressor issues, it’s essential to diagnose the root cause accurately and apply appropriate solutions. Here are some proven repair techniques:

- Seal Replacement: Replace worn or damaged seals to prevent air leaks and maintain proper compression efficiency.

- Valve Repair: Inspect and repair or replace malfunctioning valves to ensure proper airflow and pressure regulation.

- Bearing Maintenance: Regularly inspect and lubricate bearings to prevent overheating and premature failure.

- Cooling System Upgrades: Upgrade cooling systems or add auxiliary cooling equipment to prevent overheating and improve thermal management.

- Oil Analysis: Conduct regular oil analysis to detect contaminants and monitor lubricant condition, allowing for timely oil changes and contamination prevention.

Conclusion

Industrial compressor repair requires a combination of preventive maintenance, proactive troubleshooting, and effective repair techniques. By following the best practices outlined in this guide and implementing proven solutions, you can ensure the reliable operation of your compressors, minimize downtime, and optimize productivity in your industrial facility. Remember to consult with qualified technicians and adhere to manufacturer guidelines for safe and efficient compressor repair and maintenance.